In the efforts to protect employees from kidney disease, lung cancer, silicosis, and chronic obstructive pulmonary disease caused by exposure to respirable crystalline silica, the Occupational Safety and Health Administration (OSHA) plans to limit their contact to this type of dust.

By reducing their permissible exposure limit to 50 micrograms per cubic meter of air over an 8-hour shift, they hope to greatly reduce the diagnosis and death caused by diseases such as silicosis. Key provisions include engineering controls to limit exposure, developing written exposure control plans, offering medical exams to highly exposed workers, and training workers about silica risks.

Crystalline silica is a basic component of a combination of minerals that can become respirable size particle when works chip, cut, grind, or drill objects that contain this item. Concrete is a common material where crystalline silica is found, which can lead to an array of problems when your business is looking to install a permanent ESD floor. Not only does this call for specific monitoring, it can delay your installation when crystalline silica levels are too high to work safely.

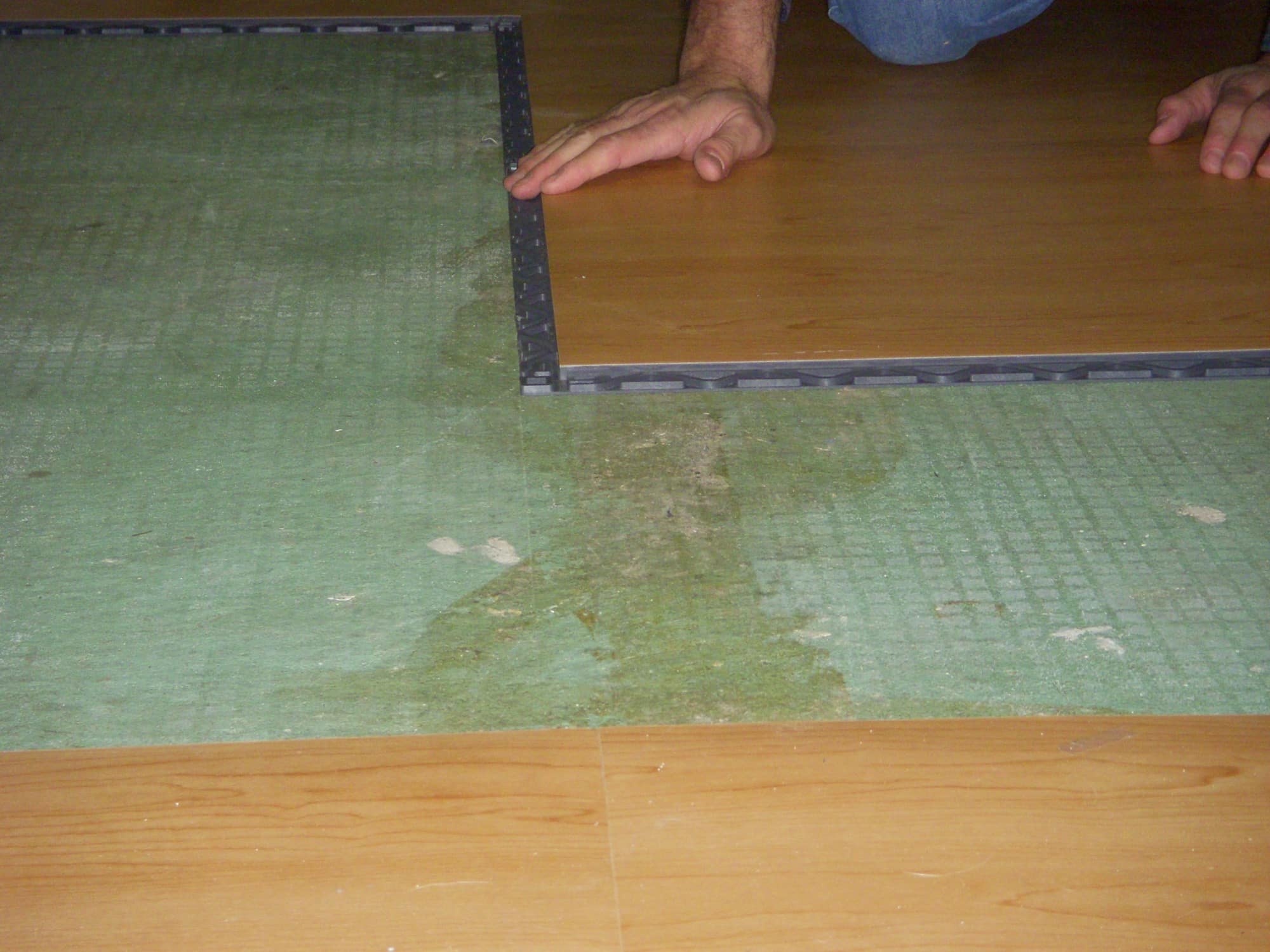

Luckily, when you use StaticStop’s interlocking ESD tile, you will never have to worry about crystalline silica because our products involve no grinding, drilling, or nearly any preparation to install. We have the only interlocking ESD flooring with zero disclaimers for high-moisture, irregular, or problem subfloors. In a much shorter time, our floors can be installed over your problem concrete without risking the exposure of crystalline silica to any employees that enter your facility. And if you ever happen to move your business, you can take our tiles with you simply by disconnecting the interlock.

With more questions about our interlocking ESD flooring and how we can help you avoid delays or complications in your renovation, call our experts today at (508) 583-3200.