No matter if you are working in a residential or commercial space, it is common for these structures’ bottom floors to be constructed with poured concrete. Though concrete is known to be extremely durable, it is also porous and conducts the temperature and moisture of the ground on which it is sitting. This can cause many problems with your ESD flooring from the start.

If your subfloor has high-moisture, it can result in high acidity in the concrete itself. This can throw off the pH levels, and impact the way the subfloor reacts to the adhesive used to attach your ESD flooring. Without the proper bond between your subfloors and your ESD product, you will often find your ESD flooring failing.

These simple facts alone are the number one reason ESD flooring fails. There are many steps you can take to prepare your concrete floors for this specialized flooring, such as hiring a professional team to install plastic vapor barriers or a moisture barrier coating, but we have a better idea for you.

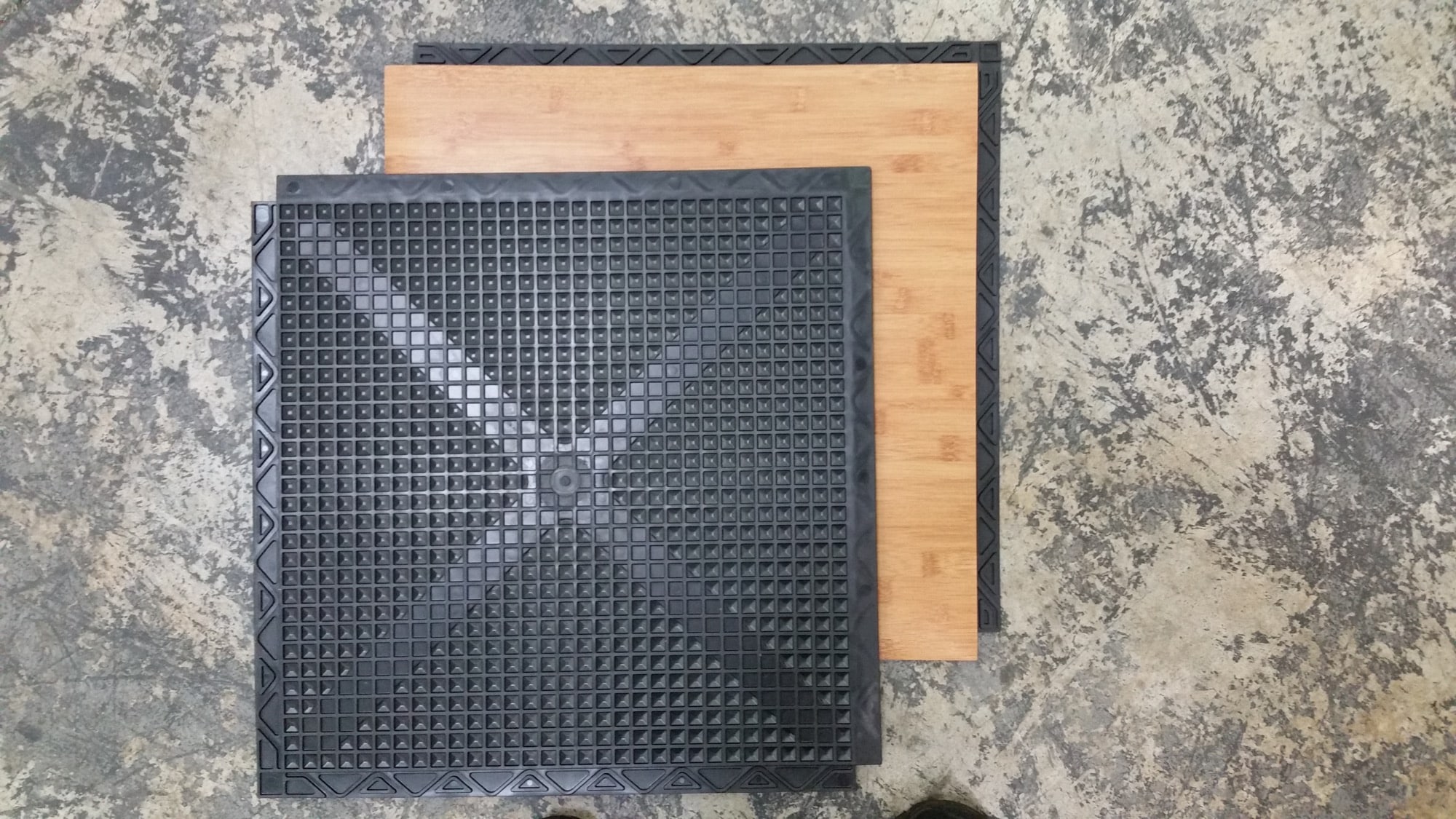

StaticStop’s conducive floor tiles are the only interlocking ESD products available with no disclaimers for irregular, problem, and high-moisture subfloors. It can easily be installed by your crew without our assistance. This means you spend less time prepping and installing your ESD floors, and allow you more time to go back to your work with minimal disruptions to your usual production.

The benefits of our flooring tiles are endless, and can even sound too good to be true. StaticStop would love to explain to you all of the reasons our products work and how it can save you both time and money. With more questions about our interlocking conductive floor tile and how it can work for your business, call us today at (508) 583-3200.