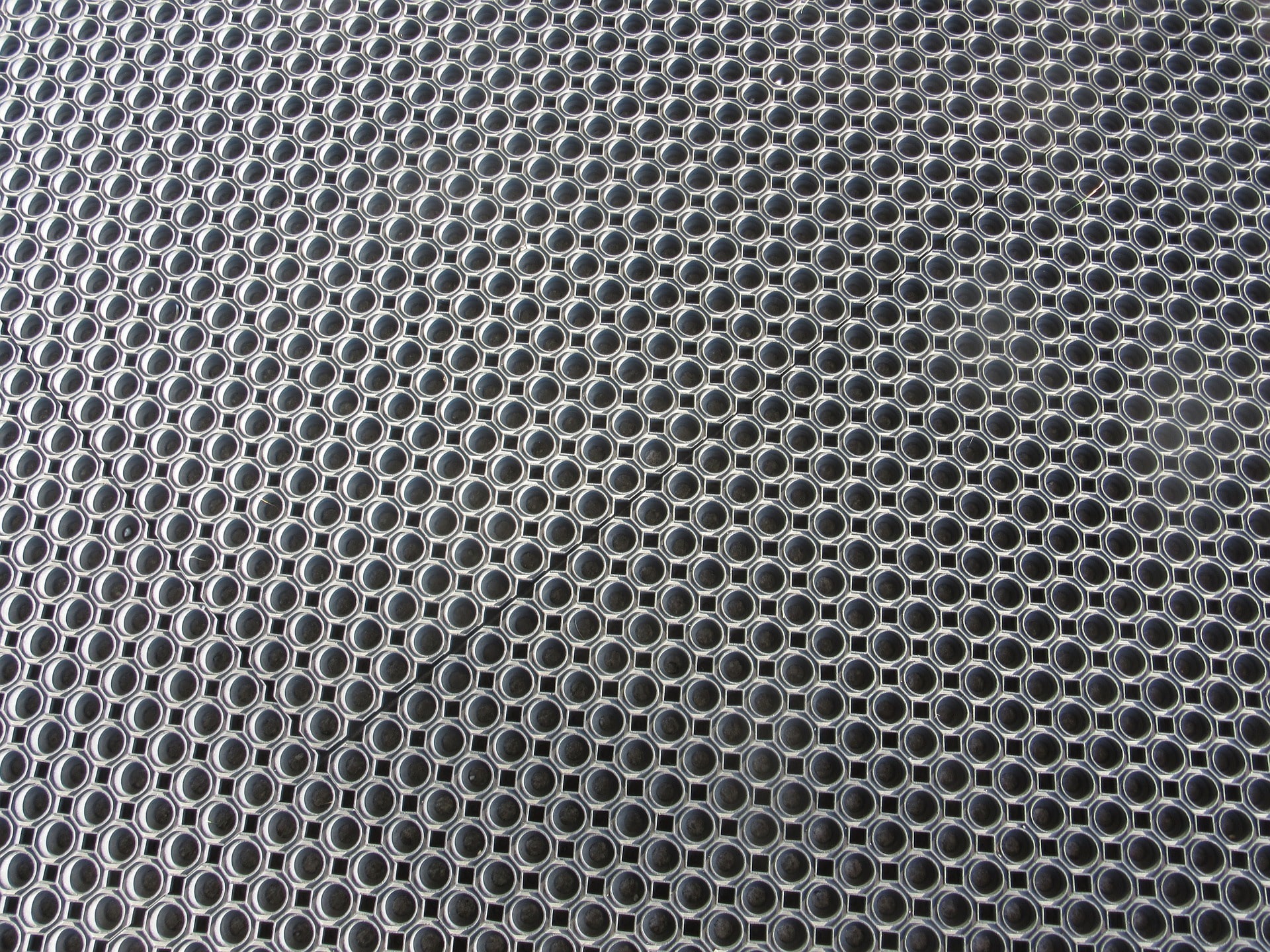

One popular method of making sure your flooring is ESD safe is to include rubber in the flooring. Rubber is a material that doesn’t conduct electricity, and so it can stop static discharge before it becomes harmful. We’ve got options that utilize rubber in flooring—check out why it’s a good option.

Rubber is very durable. If you need flooring in a high-traffic area, this option allows you to make sure the flooring will stand up and last for years. You can also find options with a top layer that isn’t made of rubber so that your floor can look like wood or carpet while withstanding the traffic.

Rubber is also a low maintenance material. You don’t need to spend a lot of time taking care of it to make sure it stands up to the traffic or environmental conditions. Install the flooring, give it maintenance once in a while, and you’re good to go.

Rubber is also perfect for flooring in areas where people are on their feet all day. The little spring from the rubber helps with ergonomics and makes standing or walking far more comfortable. If you’re putting flooring in a lab or workshop where people won’t be sitting, consider rubber for its ergonomic properties as well as ESD.

The material can also create a sound barrier between floors of a building. Rubber absorbs sound and acts as a dampener between stories. Your downstairs neighbor won’t hear you, and you won’t have to worry about the interruptions from other floors.

In addition to protecting you from static discharge, rubber flooring is water resistant. The building beneath the flooring will be protected from liquid spills or floods that might occur—you won’t need to worry about damaging the building itself if an accident happens.